Welcome to China Australia rubber!

|

Entry name |

Coal to gas project |

||||||||

|

Construction unit |

Hebei Zhongao Rubber Co., Ltd. |

||||||||

|

Legal representative |

Yu Zichao |

Contact person |

Yu Zengji |

||||||

|

Postal address |

Hebei Zhongao Rubber Co., Ltd. |

||||||||

|

Contact number |

13731213290 |

Fax |

|

Postal Code |

071300 |

||||

|

Construction site |

In the rubber industrial park of Boye County |

||||||||

|

Project approval department |

|

Approval number |

|

||||||

|

Nature of construction |

Technical transformation |

Industry category and code |

Heat production and supply D 4430 |

||||||

|

Area covered |

50 |

Afforested area |

|

||||||

|

Total investment |

30 |

Including: environmental protection investment(Ten thousand yuan) |

1 |

Proportion of environmental protection investment in total investment |

3.3% |

||||

|

Evaluation funds |

|

Expected commissioning date |

March 2017 |

||||||

Located in the rubber industrial park of Boye County, Hebei Zhongao Rubber Co., Ltd. produces 600000 square meters of rubber belts annually. In April 2013, the enterprise commissioned the EIA unit to prepare the environmental impact report of the conveyor belt production line construction project of Hebei Zhongao Rubber Co., Ltd. in July 2013, the environmental impact report of the conveyor belt production line construction project of Hebei Zhongao Rubber Co., Ltd. passed the examination and approval of Boye county environmental protection Bureau (bohuanshu [2013] No. 23, see Annex 2), and passed the examination and approval of Boye County Environmental Protection Bureau in April 2016 (BHY [2016] No.07, see Annex 3). According to the work plan for dismantling and replacing coal-fired boilers for production and operation in Boye County in 2016, the existing coal-fired boilers of the enterprise have been included in the elimination and transformation plan of coal-fired boilers in Boye County in 2017. Considering the requirements of energy conservation, emission reduction and environmental protection management, the project will eliminate the existing 2 T / h coal-fired boilers (one for use and one for standby) and build a new yqw-930 Q (1.3 T / h) gas-fired boiler. According to the site survey, the coal-fired boiler in the plant has been removed.

According to the law of the people's Republic of China on environmental impact assessment, the State Council Order No. 253 regulations on the administration of environmental protection of construction projects, and the Ministry of environmental protection order No. 33 catalogue of classified administration of environmental impact assessment of construction projects, the project needs to go through the EIA procedures and prepare the environmental impact report. Therefore, Hebei Zhongao Rubber Co., Ltd. entrusts Hebei Shuimei Environmental Protection Technology Co., Ltd. to undertake the environmental impact assessment of the project. After receiving the entrustment, our company immediately organized technical personnel to go to the site to survey the project site and surrounding environment, collected the technical data and relevant documents related to the project, and prepared the environmental impact report of coal to gas project of Hebei Sino Australia Rubber Co., Ltd.

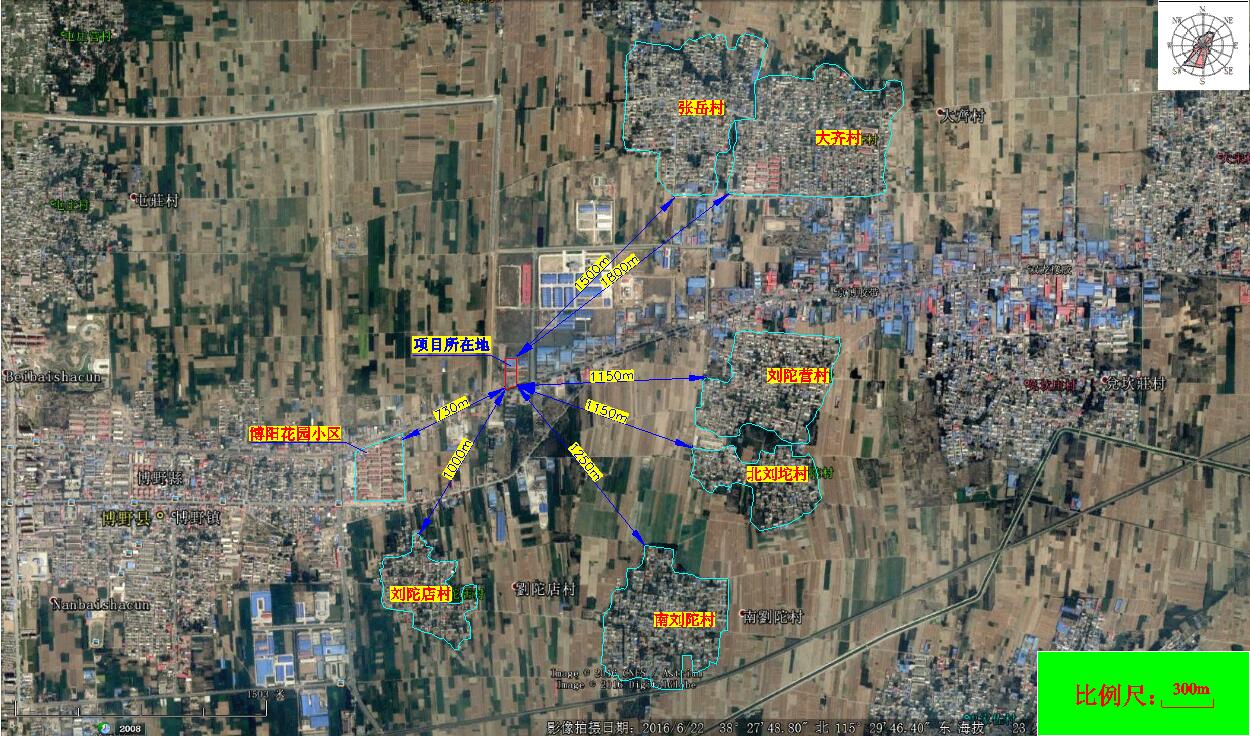

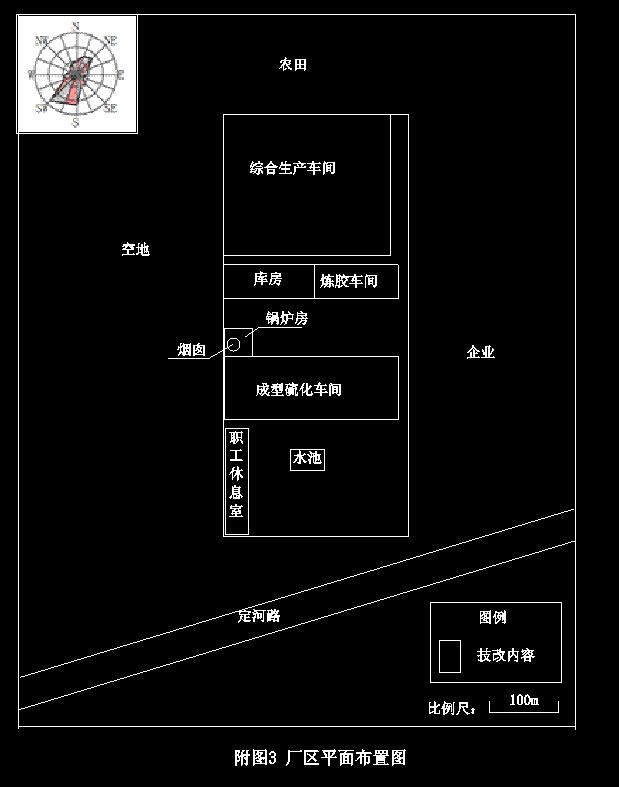

(1) Construction site and surrounding relationship

The technical transformation project is located in the rubber industrial zone of Boye county. The center of the plant site is 115 ° 29 ′ 16.8 ″ E and 38 ° 27 ′ 48.2 ″ n. Hebei Zhongao Rubber Co., Ltd. is an enterprise in the East, road in the west, DINGHE road in the South and farmland in the north. The technical transformation project is located in the southwest of the plant. The west side is the boundary of the plant, the east side is the open space of the plant, the south side is the molding and vulcanization workshop, and the north side is the warehouse, rubber mixing workshop and comprehensive production workshop. The nearest sensitive point to the project is Boyang Garden community 730m to the southwest of the project.

The geographical location of the project is shown in Figure 1, and the surrounding relationship is shown in Figure 2.

(2) Construction content and scale

The existing coal-fired boiler room of the enterprise is located in the southwest of the plant, covering an area of 50m2 and building area. There are two 2T / h coal-fired boilers (one for use and one for standby) in the room, which are used for production and office heating in winter.

In this reconstruction project, the existing boiler room is used, the original coal-fired boiler is demolished, a new gas-fired boiler is built, and a yqw-930 Q (1.3 T / h) gas-fired boiler is installed to provide heat for the production and living areas.

After the technical transformation, the natural gas consumption of the boiler is about 2.858 million m3 / h (about 24.875 A / h) according to the heat consumption of coal and natural gas.

(3) Raw and auxiliary materials and energy consumption

-fareast- language:ZH-CN;mso-bidi-language 3 T / h). According to the site survey, the coal-fired boiler in the plant has been removed.

See Table 1 for main raw materials and energy consumption of technical transformation project.

Table 1 list of raw and auxiliary materials and energy consumption of the project

|

Serial number |

Category |

Name |

Consumption |

|

1 |

Energy consumption |

Natural gas |

24.8ten thousandm3/a |

(4) Main equipment

The main production equipment of the technical transformation project is shown in Table 2.

Table 2 list of main production equipment of technical transformation project

|

Serial number |

Equipment name |

Quantity (set / set) |

Specification and model |

|

1 |

Gas fired boiler |

1 |

YQW-930 Q(1.3t/h) |

|

2 |

Water softening system |

1 |

-- |

|

3 |

Surge pump house |

1 |

-- |

(5) Public works

1) Water supply and drainage

① Water supply

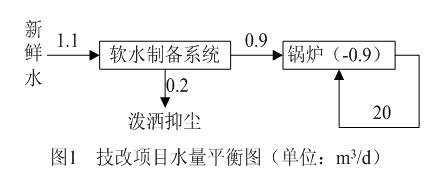

The water for this project is supplied by the self provided well to make up water for the boiler. The water consumption is 1.1m3/d (330m3 / a), which can meet the needs of the project.

② Drainage

The wastewater of the project is discharged from the soft water preparation system, with a discharge capacity of 0.2m3/d (60m3 / a), which is used for sprinkling and dust suppression in the plant area.

The water consumption balance diagram of the project is shown in Figure 1.

(2) Power supply engineering

The power supply of the project relies on the existing project and is supplied by Boye County Power Supply Bureau.

3) Gas supply project

The gas for this project is provided by Aode Gas Co., Ltd. of Boye county. The gas supply agreement has been signed (see Annex 6).

The main components of natural gas are shown in Table 3.

|

Water content |

Ash content |

Sulphur content |

Low calorific value |

|

6% |

9.8% |

200mg/m3 |

31.4MJ/kg |

(6) Labor quota and production time system

After the completion of the technical reform project, 2 staff are required, which are allocated by the existing staff internally without adding new labor quota; the working system is 300 days of work and 24 hours per day; the boiler operation time is 9.5h/d (2850h/a).

(7) Construction nature and construction stage

This project belongs to the technical reform project, and has been completed.

Original pollution and main environmental problems related to the project:

Original pollution related to the project

According to the original EIA and approval, acceptance report and emission permit monitoring report, the pollutant generation of the project is as follows:

(1) Exhaust gas

The current project consumes 300t / a of coal and 4.5 million m3 / a of flue gas. According to the original environmental assessment and acceptance monitoring report, after the waste gas is treated by water bath dust collector (alkali addition), the particulate matter, SO2 and discharge concentration are 160mg/m3 and 682.4mg/m3 respectively, which are in accordance with the emission standard of boiler air pollutants (gb13271-2014). NOx emission concentration is 380mg/m3, which meets the standard in Table 1 of emission standard for nitrogen oxides of coal fired boiler (db13/2170-2015). The emission of flue gas pollutants of existing projects are: particle 0.72t/a, so23.07t/a and nox0.882t/a.

(2) Noise

According to the enterprise acceptance monitoring report, noise values of each boundary are: in daytime: 62.3db (a) in the east boundary, 60.4db (a) in the north boundary, 62.9db (a) at the west boundary, 63.4db (a) in the south boundary; at night: 51.2db (a) of the East boundary, 53.2db (a) in the north, 53.0db (a) in the west boundary, 54.4db (a) in the south boundary. The noise at the south boundary meets the class 4 standard of emission standard for industrial enterprise boundary environmental noise (gb12348-2008), and the rest of the boundary meets the class 3 standard of emission standard for industrial enterprise boundary environmental noise (gb12348-2008).

(3) Solid waste

The existing projects mainly include boiler slag and dust dust, all of which are properly disposed.

(4) Total control index

The total control indexes of the existing projects are: smoke and dust: 0.72t/a; so2:3.07t/a; nox:0.882t/a.

Brief introduction of the natural environment and social environment of the construction project site

Brief introduction of natural environment (topography, landform, geology, climate, meteorology, hydrology, vegetation, biodiversity, etc.):

(1) Geographical location: Boye county is affiliated to Baoding City, Hebei Province, located in the middle of Hebei, the south of Baoding City in the East, and the north end of Heilonggang basin. It borders Li County in the East, Anguo City in the west, Qingyuan County in the north, Anping County and Raoyang County in Hengshui City in the south. Shuozhou Huanghua Port Railway (Shuozhou Huangdao railway) passes through the border in the east-west direction.

Hebei Zhongao Rubber Co., Ltd. is located in the rubber industrial park of Boye county. The center of the plant site is 115 ° 29 ′ 16.8 "east longitude and 38 ° 27 ′ 48.2" north latitude. Hebei Zhongao Rubber Co., Ltd. is an enterprise in the East, road in the west, DINGHE road in the South and farmland in the north. The project is located in the southwest of the plant area, with the boundary of the plant area on the west side, the open space in the East, the molding and curing workshop in the south, the warehouse, the rubber making workshop and the comprehensive production workshop in the north. The nearest sensitive point to the project is Boyang Garden community 730m to the southwest of the project. See attached Fig. 1 for the geographical location of the project, and see Fig. 2 for schematic diagram of peripheral relationship.

There are no other natural reserves, scenic spots, ecological function reserves, cultural relics protection areas and other environmental sensitive areas around the project.

(2) Landform: the formation of landform in Boye county has experienced the long-term effect of stress inside and outside the earth, forming a typical alluvial plain of pre mountain flood. The terrain of Boye county is gentle and open. The surface slopes slowly from northwest to Southeast. After years of farmland infrastructure construction, the surface is relatively flat. The terrain of the project is flat.

(3) Climate and meteorology: Boyo County, Hebei Province, is a temperate monsoon climate area, with large temperature and humidity differences, distinct seasons, rapid spring temperature recovery, concentrated summer precipitation, high temperature and wet conditions, good autumn lighting conditions, annual average sunshine index of 2750.8 hours, average frost free period of 189 days, annual rainfall of 550-650mm, daily average temperature of 11.8 ℃, accumulated temperature above zero degree of 4710 ℃, and above 10 ℃ The accumulated temperature was 4326 ℃ for 205 days.

* (4) surface water: the average altitude of 19-29m is in Bo Ye County, Hebei province. The 5 river channels mainly consist of the Zhu long river and run across the East and West. Most of the cultivated land in this county is loam, and the west part is sandy loam. The water conservancy conditions of the county are good, the groundwater resources are rich, the buried depth of the static water level is 20.36m, and the annual average supply is 57 million cubic meters. There are 4670 wells with a watering area of over 98%. Surface water resources are mainly supplied by Shahe main channel, with an annual supply of 23.33 million cubic meters.

(5) Hydrogeology: the geological structure of Boye county is located in the southwest of Jizhong depression. The basement structure is mainly composed of faults. In the Mesozoic, the oscillatory subsidence is generated due to Yanshan movement, forming fault basin structure and stepped fault structure. The late Mesozoic Cenozoic is still in the main stage of decline, not only the thick tertiary system is deposited, and the lake and river sediments have developed in succession the west system Sediment.

The basement and cover of the formation are buried deeply in this area, which has little influence on hydrogeological conditions. The city is located in the front of the front of the alluvial fan in front of the mountain, which is basically Hutuo River alluvial fan. The stratum structure has the alluvial fan formed in different periods, which is superimposed and has certain inheritance, but also has differences. The total thickness of Quaternary strata is 500-600m. The water content becomes smaller and the water quality becomes worse. In the vertical distribution, the particles become thicker from the top to the bottom, the number of layers decreases, the thickness of the single layer increases, the head increases, and the water quality becomes better.

The groundwater flow is from northwest to Southeast, and the hydrochemical type is mainly calcium carbonate type water, followed by calcium sulfate type water. Groundwater mainly comes from the lateral recharge of atmospheric precipitation infiltration and underground runoff, followed by the return supply of surface water infiltration and artificial irrigation water.

The Quaternary aquifer is divided into four water bearing groups according to its characteristics:

The first water bearing group: Holocene Series (Q4), belonging to shallow diving, with depth of 0-70m, groundwater buried depth (March, 2000) 21-33m, lithology from west to East is coarse sand with gravel and gradual change to medium fine sand, with thickness of 40-10m, single layer thickness from 16-2.5m, common 2-6 layers, unit water inflow of 40-10m3/ (H · m), and the chemical type of water is heavy sodium carbonate-magnesium bicarbonate type water, and mineralization is 0.5-1.0g/l.

The second water bearing group: it is upper Pleistocene (Q3), belonging to the deep micro pressure bearing water bearing group, with a depth of 70-140m, and the sand layer is 50-15m from west to East, most of which is 30-20m, with layers of 4-6 layers, a single layer thickness of 23-20m, and an average unit water inflow of 20m3/ (H · m). The hydrochemical type is from calcium carbonate to magnesium bicarbonate, with mineralization degree of 0.3-0.8g/l and water temperature of 12-16 ℃, which is larger in thickness, continuous distribution, high water head and good water quality compared with the upper layer.

The first and second water bearing groups are the main mining strata at present. The hydraulic connection is more close due to the increase of mining wells, and the supply conditions are better, mainly from precipitation infiltration, river channel infiltration, field regression and underground lateral runoff.

The third water bearing group: it is middle Pleistocene (Q2), with a depth of 140-350m. From the drilling section, the sand layer is medium coarse medium fine sand with a thickness of 40-20 m, and the thickness of single layer is 17.4M, with a head higher than the upper two groups, with a unit water inflow of 26m3/ (H · m), and the hydrochemical type is sodium bicarbonate magnesium calcium water with mineralization of 0.3-0.5g/l. The water temperature is 19-20 ℃, and the water bearing group is difficult to supply, so it is not suitable to be exploited easily.

The fourth water bearing group: it is the lower Pleistocene (Q1), with a depth of more than 350m, mainly medium coarse sand, with more medium fine and fine sand. Generally, 6-10 layers, with a single layer thickness of 5-20 m, are not suitable for mining because of poor supply conditions, fine sand grains and poor water rich property.

The soil of wild area is divided into three soil groups, 6 sub classes, 13 genera and 36 soil species. There are mainly shrubs and herbs in the wild plants in China, which are rich in resources, including 31 families and 90 species, including Qiaoba and Compositae. Wild animals and plants mainly include vertebrate mammals, reptiles, fish, arthropods and insects. The endangered animals and plants are not valued in the area.

Brief introduction of social environment (socio-economic structure, education, culture, cultural relics protection, etc.):

1. introduction to social environment

Boye county is located in the hinterland of the central Hebei Plain, the middle of Hebei Province, the southern part of Baoding City, 50 km from Baoding in the north, 100 km from Shijiazhuang in the southwest and 200 km from Beijing in the north. The county covers a total area of 331 square kilometers, which has 133 administrative villages and 4 communities in 3 towns, 4 townships and 4 townships, with a total population of 256000.

Baoding Boye county is a traditional agricultural county, with all five industries, including agriculture, forestry, animal husbandry, by-products and fishing. Melon, fruit, vegetable, meat, poultry, milk and sideline processing is prosperous, and it is an important grain, cotton and oil production area and high-quality cotton production base county in Hebei Province.

Boye county has initially formed six industries, including tape, non-ferrous metal processing, food, chemical industry, light textile and machinery manufacturing, and has a relatively complete local industrial system, and the township enterprises have developed rapidly, which has become the pillar of county economy.

There are 88 schools in the county, including 76 primary schools, 9 junior high schools, 1 high school, 1 Vocational Education Center, advanced education school and special education school. There are 30326 students and 1589 vocational and educational workers in all kinds of schools in the county.

There are no special protection units such as cultural relics protection units, scenic spots, revolutionary historical sites, centralized groundwater source places and other special protection units in the vicinity of the project.

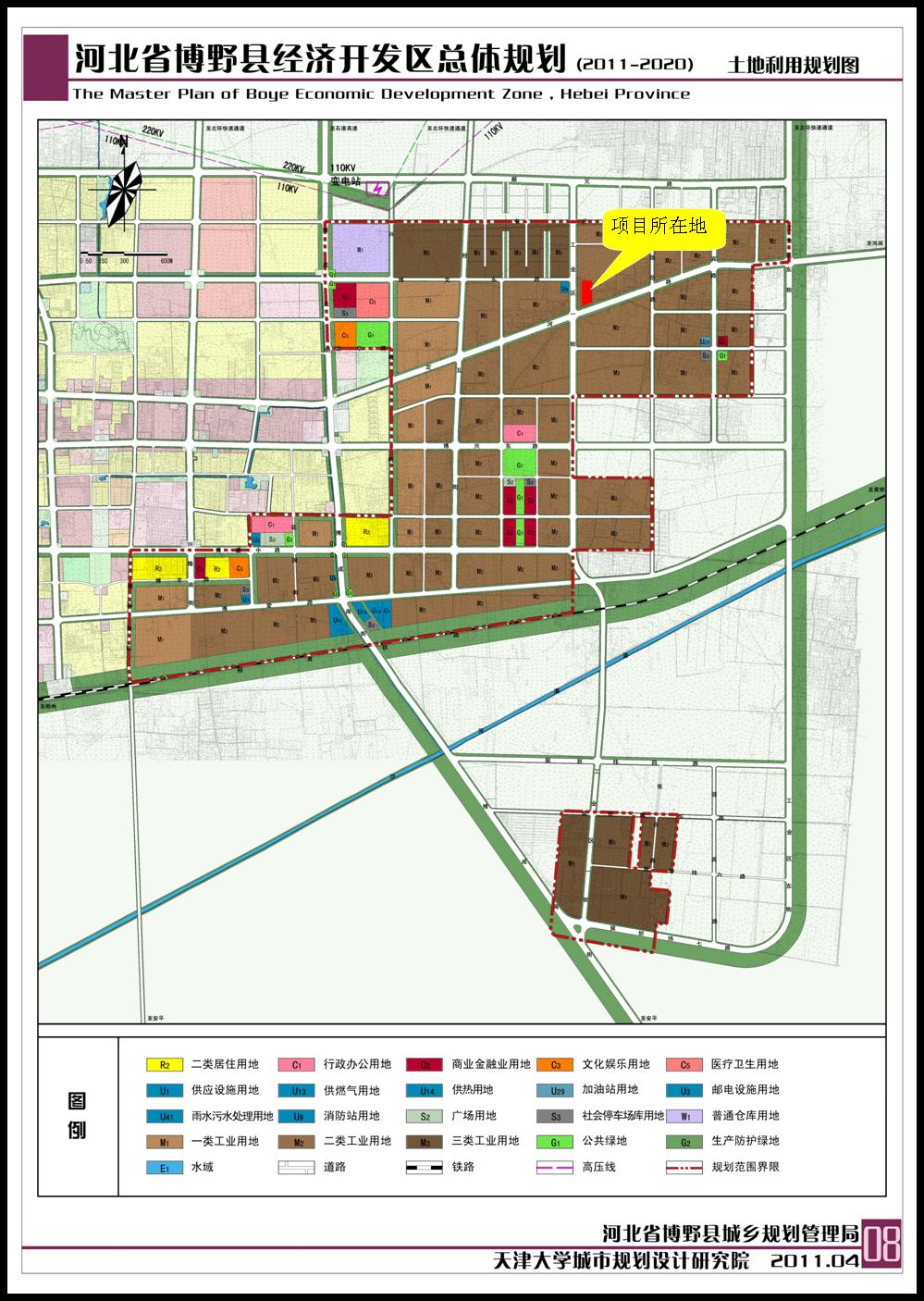

2. Detailed control planning of Boye Economic Development Zone

In July, 2011, the people's Government of Boye County commissioned the Institute of hydrogeology and environment of the Chinese Academy of Geoscience and Baoding Yida Environmental Engineering Technology Co., Ltd. to jointly prepare and complete the report on the planning environmental impact of Boye Economic Development Zone, which was reviewed by Baoding Environmental Protection Bureau in September 2012.

(1) Planning scope

Boyo economic development zone is located in the East and southeast of Boye county. It is planned to be divided into four parks, namely, urban industrial park, rubber industrial park, Chengnan Industrial Park and South economic development zone. The planned land is divided into two parts. The four to the land use scope of plot 1 (Rubber Industrial Park, Chengnan Industrial Park and Urban Industrial Park) is tunzhuang road in the north, Shuohuang Railway in the south, East is limited by East Road, ZhangYue road and Industrial Zone Street, and Xingxing street, Bocheng Street and Chaoyang Street in the west, which is in the shape of "Z", with the planned land area of 746.33 hectares; the land is located in the form of "Z" and the planned land area is 746.33 hectares; the land is located in the East The land use range of block 2 (South Zone of Economic Development Zone) is from planned Wei 5th Road to north, to planning Weiqi road in the south, 260m to the west of Yingbin Road in the East, 200m to the west of the first street of industrial zone in the west, and 67.58 hectares of land. The total planned land area is 813.91 hectares.

(2) Function positioning

The economic development zone of Boye county is built into an important industrial cluster base in the central and Southern Hebei Province and even Hebei Province; a circular economic demonstration zone with rubber belt, machinery manufacturing, non-ferrous metal processing, textile and light chemical industry cluster as the industrial orientation; a modern new development zone with complete functions, which integrates production research, logistics and Commerce and cultural display.

(3) Industrial selection and distribution of Main Parks

Boye Economic Development Zone has determined that rubber belt, machinery manufacturing, non-ferrous metal processing, textile and light chemical industry are the main industries, forming four industrial parks: Chengnan Industrial Park, Economic Development Zone South District, rubber industrial park and urban industrial park. The South industrial zone is located in the north of Shuohuang Railway and on both sides of boyai Road, mainly developing non-ferrous metal processing and textile industries; the rubber industrial park is located on both sides of DINGHE Road, mainly developing rubber belt, machinery manufacturing and other industries.

See Table 4 for industrial selection and distribution of main parks in economic development zone.

Table 4 industrial selection and distribution of main parks in Economic Development Zone

|

Main zoning of Economic Development Zone |

Position |

Major development industries |

|

Rubber Industrial Park |

On both sides of DINGHE Road |

Rubber machine belt, machinery manufacturing |

|

South District of Economic Development Zone |

South of Shuohuang Railway and east of Bocheng highway |

Light chemical and agricultural industrialization projects |

|

Urban Industrial Park |

North of Bosheng Road, both sides of Xingwang Street |

Urban industry |

|

Chengnan Industrial Park |

North of Shuohuang Railway and on both sides of Boai Road |

Non ferrous metal processing, prevention and treatment |

The project is located in the second type industrial land of rubber industrial park of the Development Zone, which conforms to the industrial orientation and land use planning of the park. See Fig. 4 for the spatial structure plan of the development zone and Fig. 5 for the land use plan.

(4) Planning period

The planning period is: 2011-2015 in the near future and 2016-2020 in the long term.

(5) Park access conditions

① Rubber track, machinery manufacturing and related industrial projects can be entered into the park. Industries that do not conform to the industrial orientation and the pollution emission of Boye economic development zone are not allowed to enter the park, such as dyeing and finishing industry, leather industry, paper making industry, electroplating industry, smelting industry, etc.

② It is in line with the industrial positioning, but belongs to the restricted items in the catalogue of guidance for industrial structure adjustment (2011 version); the project using the backward production process equipment eliminated in the guidance catalogue of industrial structure adjustment (2011 version); the project that produces the backward products eliminated in the guidance catalogue for industrial structure adjustment (2011 version); the project does not meet the requirements of economic scale and economic effect Enterprises with poor interests and serious pollution shall not enter the park.

③ It is forbidden to develop heavy pollution chemical projects mainly based on waste gas.

The enterprise is a rubber belt production project, and the industrial positioning and land occupation meet the planning requirements of the park.

(6) Supporting public works in the Development Zone

1) Water supply and drainage project planning

① Water supply planning

Groundwater is used for water supply in the planning area in the near future, and it is introduced from the water source of South to North Water Diversion in the long term.

② Drainage project planning

The drainage water in the economic development zone is divided into two systems: rain and sewage. The sewage pipe and rainwater pipe make full use of the terrain and terrain for gravity drainage.

2) Heating engineering planning

The thermal power of the economic development zone is gas source, which is led from the west to east gas pipeline at the intersection of Bosheng South Street and boyai road. The heating in the economic development zone is supplied by a boiler room located in the south side of South Street of the Development Zone, adjacent to the natural valve station.

3) Gas engineering planning

The gas source of economic development zone adopts the west to east gas transmission. The gas is from the natural valve station at the intersection of South Street and boyai road.

The gas of the project is provided by Boye County ode Gas Co., Ltd. and gas supply agreement has been signed (see Annex 6). The natural gas heating network has been laid to the project location.

environmental quality conditions

The current situation of environmental quality and main environmental problems in the area where the construction project is located (environmental air, surface water, groundwater, acoustic environment, ecological environment, etc.):

(1) Ambient air

The average value of SO2, No21, 24-hour average and annual average value meet the secondary standard of ambient air quality standard (gb3095-2012); the annual average value of PM10 and 24-hour mean value exceed the standard in winter and spring due to the northern climate.

(2) Groundwater

The environmental quality of groundwater is in good condition, which conforms to class III standard of groundwater quality standard (GB / t14848-93).

(3) Acoustic environment

The regional acoustic environment shall comply with the class 3 sound environment functional area standard of the sound environment quality standard (gb3096-2008), and the class 4A standard of the standard shall be implemented within 25m on both sides of DINGHE road.

Main environmental protection objectives (list and protection level):

According to the pollutant emission characteristics, distribution of environmental sensitive points around the project and requirements of environmental function, the main environmental protection objectives and protection levels of the project are determined. See Table 5:

Table 5 list of environmental protection objectives and protection levels of the project

|

Environmental elements |

Protection target |

Position |

Distance(m) |

Protected objects |

Protection level |

|

Ambient air |

Boyang Garden Community |

SW |

730 |

Resident |

Class II standard of ambient air quality standard (gb3095-2012) |

|

Liutuodian Village |

SW |

1000 |

Resident |

||

|

Liutuodian Village |

E |

1150 |

Resident |

||

|

Beiliutuo Village |

SE |

1100 |

Resident |

||

|

Nanliutuo Village |

SE |

1250 |

Resident |

||

|

Zhang Yuecun |

NE |

1500 |

Resident |

||

|

Daqi Village |

NE |

1800 |

Resident |

||

|

Groundwater |

Groundwater |

Underground water in and around the plant |

Groundwater |

Class III standard of quality standard for groundwater (GB / t14848-93) |

|

Applicable standards for evaluation

(1) Ambient air: implement the secondary standard of ambient air quality standard (gb3095-2012).

(2) Groundwater: Class III standard of quality standard for groundwater (GB / t14848-93) shall be implemented.

(3) Acoustic environment: the acoustic environment quality of the project area shall comply with the requirements of class 3 area standard of "acoustic environment quality standard" (gb3096-2008), and class 4A standard of this standard shall be implemented within 25m on both sides of DINGHE road.

The environmental quality standards and limits are shown in Table 6.

Table 6 list of environmental quality standards and limits

|

Project |

Evaluation factors |

Standard value |

Standard sources |

|

Atmospheric environment |

SO2 |

24Hourly average≤150μg/m3 |

Class II standard of ambient air quality standard (gb3095-2012) |

|

NO2 |

24Hourly average≤80μg/m3 |

||

|

PM10 |

24Hourly average≤150μg/m3 |

||

|

CO |

24Hourly average≤4mg/m3 |

||

|

PM2.5 |

24Hourly average≤75μg/m3 |

||

|

Groundwater environment |

pH Ammonia nitrogen Permanganate index Nitrate nitrogen Nitrite nitrogen Total dissolved solids |

6.5~8.5 |

Groundwater quality standard(GB / t14848-93) class III standard |

|

Acoustic environment |

Leq(A) |

Daytime≤65dB(A) |

Class 3 area standard of environmental quality standard for noise (gb3096-2008) |

|

Leq(A) |

Daytime≤70dB(A) |

Category 4A standard of environmental quality standard for noise (gb3096-2008) |

(1) The emission of boiler flue gas shall comply with the emission standard of gas-fired boiler in Table 3 of emission standard of air pollutants for boilers (gb13271-2014).

(2) The environmental noise emission at the south boundary is in accordance with the requirements of class 4 standard of emission standard for industrial enterprises noise at boundary (GB 12348-2008), and class 3 standard for other boundary.

See Table 7 for pollutant emission standards.

Table 7 list of pollutant emission standards

|

Project |

Evaluation factors |

Standard value |

Standard sources |

|

Waste gas |

Particulate matter |

20mg/m3 |

Table 3 emission limits for gas fired boilers in emission standard of air pollutants for boilers (GB 13271-2014) |

|

SO2 |

50mg/m3 |

||

|

NOX |

150mg/m3 |

||

|

Noise |

Leq(A) |

Daytime≤70dB(A) |

The noise at the south boundary is in accordance with the environmental noise emission limits of class 4 sound function areas specified in the emission standard for industrial enterprises noise at boundary (GB 12348-2008) |

|

Leq(A) |

Daytime≤65dB(A) |

Other boundary noise shall comply with the environmental noise emission limits of class 3 sound function areas specified in the emission standard for industrial enterprises noise at boundary (GB 12348-2008) |

After the completion of this technical reform project, the recommended indicators for total flue gas control of boiler are shown in Table 8

Table 8 list of total flue gas control indexes of boiler before and after the completion of the project unit:t/a

|

Contaminants |

Total pollutant control index of coal fired boiler in existing projects |

Total pollutant control index of gas boiler in technical reform project |

Increase and decrease before and after technical transformation |

|

Particulate matter |

0.72 |

0.061 |

-0.659 |

|

SO2 |

3.07 |

0.162 |

-2.908 |

|

NOX |

0.882 |

0.490 |

-0.392 |

After the completion of the technical reform project, the actual emission of boiler flue gas pollutants is taken as the recommended value of total pollutant emission control index, which are: particle 0.061t/a, so20.162t/a, nox0.490t/a.

Analysis of construction project

Brief description of process flow (Figure):

The coal to gas project of this technical reform project has completed the installation and commissioning of boiler equipment by using the existing boiler room. Therefore, the following is only a brief analysis of the process flow during the operation period of the boiler.

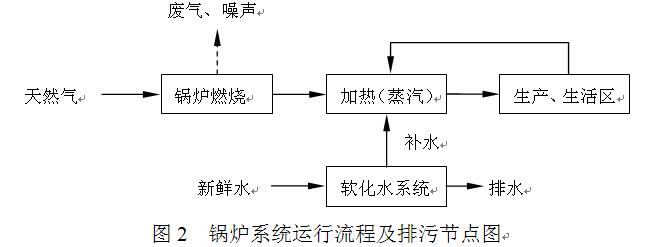

Brief introduction of boiler operation process: the soft water required by the boiler of the project is processed by the soft water preparation system and injected into the gas boiler; the natural gas used in the project is stored by tank car, and the natural gas enters the gas boiler through special pipelines for combustion. The soft water in the boiler becomes high-temperature steam by heating, and the circulating water pump sends the steam to the production and living area, and the remaining hot water is returned to the boiler after use Recycle, supplement the pipeline system loss and discharge loss water quantity regularly.

Main pollution process:

See Table 9 for the sewage nodes of each process of the project.

Table 9 list of sewage nodes in each process of the project

|

Category |

Pollution sources |

Sewage node |

Contaminants |

Emission law |

Governance measures |

|

Waste gas |

Natural gas boiler |

G1 |

SO2 |

Continuity |

It is discharged from a chimney not less than 8m |

|

NOX |

Continuity |

||||

|

Particulate matter |

Continuity |

||||

|

Noise |

Fan, pump and other equipment |

N1 |

Equivalent continuous a sound level |

Continuity |

Vibration reduction of foundation and sound insulation of workshop |

|

Waste water |

Drainage of softened water system |

W1 |

COD、SS、Ammonia nitrogen |

Intermission |

Spray water to suppress dust |

Production and expected discharge of main pollutants in the project

|

Content type |

Emission sources |

Name of pollutant |

Production concentration and quantity before treatment(unit) |

Emission concentration and quantity(unit) |

|

Atmospheric pollutant |

Boiler flue gas |

SO2 |

48mg/m3,0.162t/a |

48mg/m3,0.162t/a |

|

NOX |

145mg/m3,0.490t/a |

145mg/m3,0.490t/a |

||

|

Particulate matter |

18mg/m3,0.061t/a |

18mg/m3,0.061t/a |

||

|

Water pollutants |

-- |

-- |

-- |

-- |

|

Solid waste |

-- |

-- |

-- |

-- |

|

Noise |

The noise equipment of the project is boiler blower, feed pump, etc., with the sound pressure level between 85-95db (a). The construction unit selects low-noise equipment and maintains it regularly. The feed pump and the fan are both placed in the boiler room, and the foundation is vibration-proof. After the above noise reduction measures are taken, the noise at the East, West and north boundary meets the class 3 standard of emission standard for industrial enterprise boundary environmental noise (gb12348-2008), and the south boundary meets the class 4 standard. |

|||

|

Main ecological impacts: The project will be constructed in the existing plant area without new land acquisition. It will not affect the ecological environment. |

||||

Environmental impact analysis

Brief analysis of environmental impact during construction period:

The technical transformation project uses the existing boiler room in the plant area for technical transformation, which has been completed. Therefore, the environmental impact analysis during the construction period is no longer carried out.

Environmental impact analysis during operation period:

1. Atmospheric environmental impact analysis

The main environmental impact during the operation period of the project is boiler flue gas.

The boiler of this project is 1.3t/h natural gas boiler, and the natural gas consumption is 248000 m3 / A. According to the reference value of the industrial boiler (thermal production and supply industry) in the first national census of industrial pollution sources, the amount of flue gas produced by the project is 3.38 × 106m3 / A, the amount of pollutants produced is 0.061t/a of particulate matter, 0.162t/a of so20, 0.490t/a of NOx, and the concentration of pollutants produced is 0.061t/a Particulate matter 18 mg / m3, so248 mg / m3, nox145 mg / m3. The boiler flue gas is discharged through a chimney no less than 8m high. The boiler flue gas emission concentration of the project meets the emission limits of gas-fired boilers in Table 3 of emission standard of air pollutants for boilers (gb13271-2014). The pollutant emissions of gas-fired boilers are 0.061t/a of particulate matter, 0.162t/a of so20 and 0.490t/a of NOx respectively.

After the completion of the technical transformation, the emission reductions of particulate matter, SO2 and NOx are 0.659t/a, 2.908t/a and 0.392t/a respectively, which greatly reduces the impact of boiler flue gas on the surrounding atmospheric environment and significantly improves the ambient air.

2. Water environment impact analysis

The waste water of this project is soft water preparation system drainage, which is pure water. It is all used for dust suppression in the plant area, and will not affect the surface water and groundwater environment.

3. Acoustic environmental impact analysis

The main noise source of the project is the noise generated by the operation of fans, pumps and other equipment, and the source intensity is about 80 ~ 95dB (a). The noise equipment of the project is located in the plant, the fans are installed with mufflers, and the pumps are installed with damping pads. After taking measures, the noise reduction amount of noise equipment can reach 15-30db (a), which can ensure that the noise of East, West and north boundary can meet the class 3 standard of "emission standard for industrial enterprises noise at boundary" (gb12348-2008), and that of south boundary can meet the class 4 standard. The project is 730m away from the nearest sensitive point Boyang Garden community. After distance attenuation, it will not have adverse impact on the surrounding acoustic environment.

4. "Three accounts" of pollutant discharge after completion of technical transformation project

See table 10 for the "three accounts" of pollutant emission after the completion of the technical transformation project.

Table 10 list of "three accounts" of boiler flue gas pollutant emission after completion of technical transformation project

|

Contaminants |

Emission of pollutants from coal fired boilers of existing projects |

Reduce the old with the new |

Gas fired boiler of technical reform project pollutant discharge level |

Pollutant emission of gas fired boiler after completion of technical transformation project |

|

Particulate matter |

0.72 |

0.72 |

0.061 |

0.061 |

|

SO2 |

3.07 |

3.07 |

0.162 |

0.162 |

|

NOX |

0.882 |

0.882 |

0.490 |

0.490 |

Prevention and control measures adopted in construction project and expected control effect

|

Content type |

Emission sources |

Name of pollutant |

Prevention and control measures |

Expected governance effect |

|

Atmospheric pollutant |

Boiler flue gas |

SO2 |

No less than 8m stack discharge |

It meets the emission limits of gas-fired boilers in Table 3 of emission standard of air pollutants for boilers (gb13271-2014). |

|

NOX |

||||

|

Particulate matter |

||||

|

Water pollutants |

-- |

-- |

-- |

-- |

|

Solid waste |

-- |

-- |

-- |

-- |

|

Noise |

The noise equipment of the project is boiler forced draft fan, feed water pump, etc., and the sound pressure level is between 85-95db (a). The construction unit selects low noise equipment and maintains it regularly. The feed water pump and forced draft fan are placed in the boiler room, and the foundation is vibration damping. After taking the above noise reduction measures, the noise at the East, West and north boundary of the project meets the class 3 standard of "emission standard for industrial enterprises noise at boundary" (gb12348-2008), and the south boundary meets the class 4 standard. |

|||

|

Ecological protection measures and expected results: The construction unit should do a good job of road hardening and greening outside the workshop, beautify the environment, and play the role of dust suppression, sound insulation and noise reduction, which is conducive to the protection of the local ecological environment. |

||||

Conclusion and suggestion

Conclusion

(1) Project overview

Project Name: coal to gas project.

Construction unit: Hebei Zhongao Rubber Co., Ltd.

Nature of Construction: technological transformation.

Project investment: 300000 yuan, environmental protection investment 10000 yuan, accounting for 3.3% of the total investment.

Personnel quota and working system: after the completion of the technical transformation project, 2 staff members are required, which are internally allocated by the existing staff without additional labor quota; the working system is 300 days per year and 24 hours per day.

Construction content: using the existing boiler room, replacing the original coal-fired boiler with gas-fired boiler, installing a 3T / h Gas-fired Boiler to provide heat for production and living areas.

Project Convergence: ① water supply: the water supply of the project is provided by the self provided well to make up water for the boiler, and the water consumption is 1.1m3/d, which can meet the demand of the project; ② drainage: the wastewater of the project is discharged by the soft water preparation system, and the discharge volume is 0.2m3/d, which is used for sprinkling and dust suppression, but not for external discharge; ③ power supply: the power supply of the project relies on the existing project and is supplied by the substation of Boye county.

(2) Conclusion of environmental impact feasibility analysis

① Waste gas: this project is a coal to gas project. After the technical transformation, the emission reductions of particulate matter, SO2 and NOx are 0.659t/a, 2.908t/a and 0.392t/a respectively. It greatly reduces the impact of boiler flue gas on the surrounding atmospheric environment, and has significant environmental benefits.

After the completion of the technical transformation, the emission concentration of soot, SO2 and NOx in the boiler flue gas is greatly reduced, and the emission meets the gas emission limit in Table 3 of the emission standard of air pollutants for boilers (gb13271-2014), and the ambient air is significantly improved.

② Waste water: the waste water of this project is mainly from the soft water preparation system, which is used to clean the water. It will not affect the surface water and groundwater environment by sprinkling and dust suppression.

③ Noise: the main noise source of the project is the noise generated by the operation of fans, pumps and other equipment. The noise equipment of the project is placed in the plant, the fans are installed with mufflers, and the pumps are installed with damping pads. After the measures are taken, the noise at the boundary of the plant can meet the class 3 and class 4 standards of the emission standard for industrial enterprises noise at boundary (GB 12348-2008). After distance attenuation, there is no adverse effect on the surrounding acoustic environment.

(3) Conclusion on feasibility analysis of pollution control measures

The pollution control technology adopted in the project is mature and reliable, and the prevention and control measures are feasible, which can ensure the pollutant discharge up to the standard and meet the total amount control requirements, and the regional environmental quality level can maintain the status quo.

(4) Conclusion on total emission control of pollutants

After the completion of the technical transformation project, the actual emission of boiler flue gas pollutants is taken as the recommended value of total emission control index, which is 0.061t/a of particulate matter, 0.162t/a of so20 and 0.490t/a of NOx.

(5) Contents of "three Simultaneities" acceptance

Table 11 list of "three Simultaneities" acceptance contents of environmental protection of construction project

|

Category |

Governance object |

Governance facilities |

Standard limits |

Acceptance criteria |

|

Waste gas |

Particulate matter |

It is discharged from a chimney not less than 8m high |

Emission concentration≤20mg/m3 |

Table 3 emission limits for gas fired boilers in emission standard of air pollutants for boilers (GB 13271-2014) |

|

SO2 |

Emission concentration≤50mg/m3 |

|||

|

NOX |

Emission concentration≤150mg/m3 |

|||

|

Waste water |

Drainage of soft water preparation system |

Dust suppression by sprinkling on the ground |

-- |

-- |

|

Noise |

Noise of fans and pumps |

The fan is equipped with muffler, and the pump is equipped with damping pad |

Daytime≤65dB(A) |

Class 3 standard of emission standard for noise at boundary of industrial enterprises (GB 12348-2008) |

|

Daytime≤70dB(A) |

4 standards of environmental noise emission standards for industrial enterprises (GB12348-2008) |

Enclosure

Geographical screenshot

Geographical location map

Hirono's surrounding map

Spatial structure plan

Land use plan

Fig. 2 peripheral relationship diagram

Figure 3 layout plan of plant area